The first CO2 incubator industrialized entailed a humble bell jar encompassing a lit taper. Cultures were positioned underneath the lid of the jar in conjunction with the lit taper before the jar was stimulated to a dehydrated, heated oven. This structure may be measured as the first “air-jacketed” CO2 incubator. During the late 1960s, the first enthusiastic, industrial CO2 incubators were advanced. It was during this time that New Brunswick Scientific (NBS) presented a variety of incubator goods counting the Psychrotherm, the first chilled incubator shaker, the Perfect G25 large-capacity console-style incubator shaker, and the G76 water immersion shaker. These replicas can still be found working in laboratories around the world to this day.

Inside a CO2 incubator, also recognized as a nattered incubator, an air is fashioned that is as usual as conceivable to mature cell and tissue cultures. This way of refining living creatures is called in vitro and is the main submission for CO2 incubators. The method can take numerous weeks, during which example growth and security are always the top significance. To pledge both these features, the temperature, moisture, and CO2 content must match the cell culture necessities as exactly as possible.

What is the Structure of a CO2 incubator?

A CO2 incubator made by the Co2 Incubator Manufacturers has an internal which is impenetrable from the location to defend the atmosphere within the unit and cannot be affected by outside issues. To allow laboratory specialists to still sight the samples during the development phase, most CO2 incubators contain a glass entrance as well as the regular entrance, which provides added protection against pollution.

The inner is made of rust-resistant resources such as stainless steel and must have a few sharp limits and channels as likely to evade any places where pollution could be hidden. In the subtle field of cell agriculture in specific, just one single kernel can wreck weeks of work.

The air coming in drifts through a germ-free sieve and must be dispersed consistently throughout the whole interior, as the examples are usually situated on shelves at different statures. The test lies in generating similarity throughout the entire inner, to safeguard an unchanging supply of CO2 for all examples at continuous climate and moisture conditions.

Why is CO2 required in an incubator?

Persons are most contented at CO2 planes at or somewhat above 400 ppm (0.04%) which raises the question, why would a CO2 incubator that is consumed to produce flesh cultures want CO2 planes of 5 – 10%? In instruction to culture cells under the best conditions, the modes they cultivate a desire to stay at neutral pH (around pH 7). The H2O in the cells can be twisted into a carbonic acid (H2CO3) cushion by adding extra CO2. The grouping of H2O and CO2 outcomes in bicarbonate (HCO3-) and H2CO3 which keeps the pH unbiassed, and therefore has been unearthed to affect the development of biological cells the least. In other words, by adding added CO2 at the right level you stop the pH inside the cells from becoming either chalky or acidic, which both constrain cell growth.

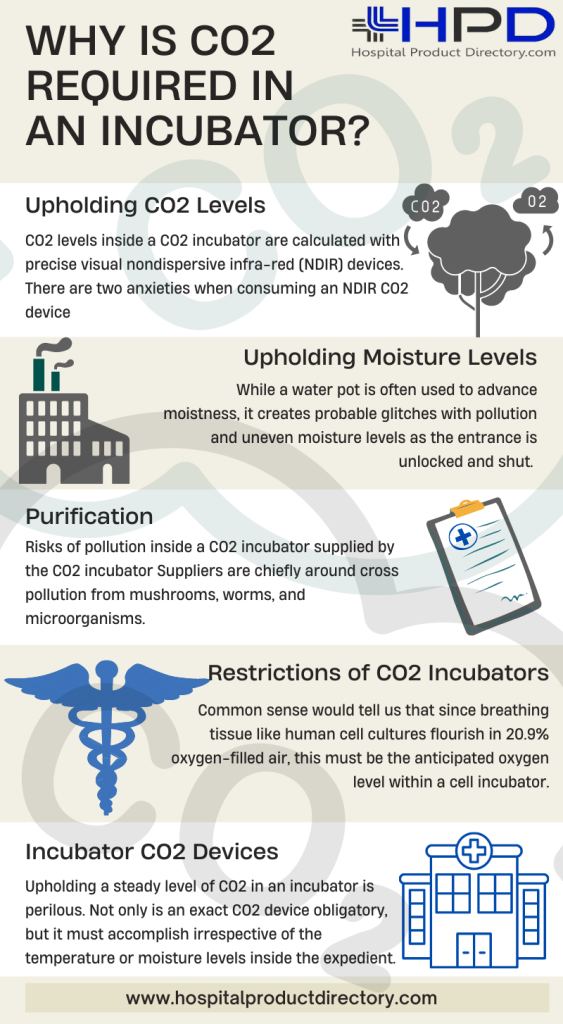

Upholding CO2 Levels

CO2 levels inside a CO2 incubator are calculated with precise visual nondispersive infra-red (NDIR) devices. There are two anxieties when consuming an NDIR CO2 device:

In high-altitude settings, the device interpretations must be attuned to the alteration in barometric pressure.

The device is protected against high moisture. Too much water in the air can consequence in a concentration inside the CO2 device which will render the device defective.

Upholding Moisture Levels

While a water pot is often used to advance moistness, it creates probable glitches with pollution and uneven moisture levels as the entrance is unlocked and shut. For that motive, an atomizer may be used to increase the moisture level along with a %RH device to control the moisture level.

Purification

Risks of pollution inside a CO2 incubator supplied by the CO2 incubator Suppliers are chiefly around cross pollution from mushrooms, worms, and microorganisms. This can be controlled by purification between examples. It is significant, however, that purification with warmth or superheated water does not come into direct interaction with the CO2 device. For this motive, the CO2 device should be combined with the incubator in such a technique that it is not impacted by the cleansing cycle. This can be set by

Gas selection CO2 device (static or handheld) outdoor the incubator

CO2 device with warmth and moisture-resistant stainless-steel top

Restrictions of CO2 Incubators

A mounting field of study is the limits of CO2 incubators as they narrate to oxygen levels. Common sense would tell us that since breathing tissue like human cell cultures flourish in 20.9% oxygen-filled air, this must be the anticipated oxygen level within a cell incubator. Since ambient air is 20.9% oxygen, CO2 incubators demand not to be wrapped from the outside air.

The conundrum is that diverse living cell cultures cultivate at diverse oxygen levels. For instance, while lung alveolar cells are unprotected to 20.9% oxygen, the oxygen level in arterial blood cascades to 10.5-13%. Many structures purpose usually at oxygen levels fluctuating from 2-8%. Rationally, revealing every cell culture to a similar 20.9% oxygen level would generate a different setting than what they were unprotected to within the body, and hence, would change cell growth consequences.

The necessity to generate anaerobic circumstances for cell cultures comprises a wide diversity of submissions including budding organ tissue portions, malignance diagnostics, genomic treatment, and worm and bacterium investigation for manufacturing, pharmacological and agrarian science.

To retort to this test, instead of consuming CO2 incubators experts use closed glove boxes with tri-gas CO2/O2/N2 gestation. The oxygen absorption is controlled by nitrogen and gauged circuitously by calculating oxygen and carbon dioxide.

Incubator CO2 Devices

Upholding a steady level of CO2 in an incubator is perilous. Not only is an exact CO2 device obligatory, but it must accomplish irrespective of the temperature or moisture levels inside the expedient. For instance, the MicroSENS IR Incubator 0-20% CO2 Sensor has been enhanced to calculate 5% by the capacity of CO2 in cell incubators to achieve perfect cell and tissue development.

Unlike archetypal CO2 devices, this device is intended to be resilient to heat and dampness. It can be enduringly installed inside the incubation cavity since it can endure up to 190° C heat and vapor sterilization. And because it can be standardized in place, it does not need to be reverted to the factory for standardization. This reduces downtime between cell culture development sequences.

What are the Other CO2 Device Choices

When it is not cost-efficient to retrofit an ancient incubator with a devoted CO2 Incubator device, other choices are available.

While not an integral solution, it can easily be applied and moved between numerous incubators to test the CO2 level from an external CO2 tank source.

CO2 incubators bought from the Co2 Incubator Dealers are the right instrument for the various procedure stages involved, such as defrosting and transporting the cells, as well as contaminating the cell lines and coloring the cell cultures. During this submission, circumstances in the internal are typically set to 37°C and 5 vol. % CO2.

The examples are examined after 72 hours at the latest. The blue pattern of the cell coating makes it possible to describe the plaque in more parts either with the bare eye or under a microscope.