Laminar flow is demarcated as airflow in which the complete body of air within a chosen space is unchanging in both speed and direction.

What is the role of a laminar flow hood?

Clean benches and biological safety cupboards are shared instances of laminar flow hoods supplied by laminar airflow Suppliers. They are laboratory inclusions intended to prudently direct HEPA-filtered air. Some of these hoods shield substances placed on the work surface from contamination. Others stop revealing the user to pollutants in the work area. Laminar flow hoods are frequently used to work with biological examples, semiconductors, or other subtle materials.

According to the CDC, the laminar airflow principle was first industrialized in the initial 1960s. It’s still extremely pertinent for modern laboratories, having factually shaped the way air securely moves in many generations of laboratory inclusions. Today, many groups of laminar flow hoods exist. Although they vary contingent on the science done within, there is one common denominator: all use this kind of unidirectional airflow to aid in upholding barrenness, stopping cross-contamination, and dipping turbulence.

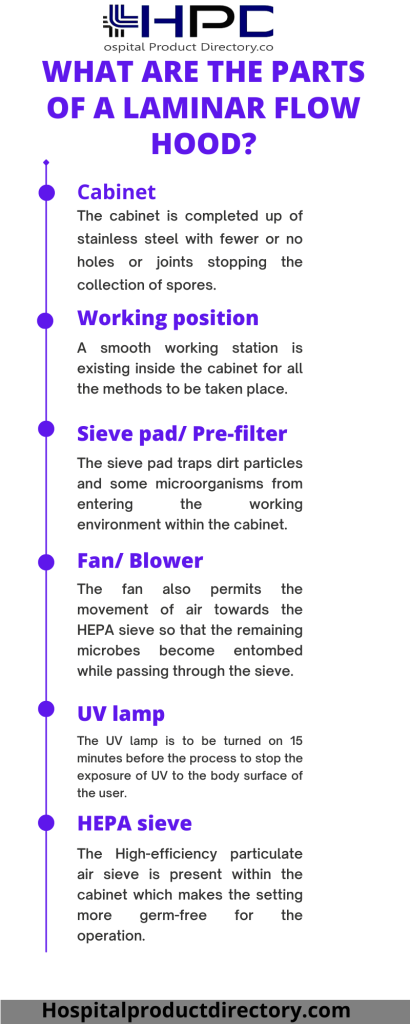

What are the parts of a laminar flow hood?

A laminar flow cupboard contains the following parts:

1. Cabinet:

· The cabinet is completed up of stainless steel with fewer or no holes or joints stopping the collection of spores.

· The cabinet delivers wadding to the inner environment shaped inside the laminar flow and defends it from the outside environment.

· The front of the cabinet is provided with a glass buffer which in some laminar cabinets opens completely or in some has two starts for the user’s hands to enter the cabinet.

2. Working position:

· A smooth working station is existing inside the cabinet for all the methods to be taken place.

· Culture plates, burner, and loops are all positioned on the working station where the process takes place.

· The counter is also made up of stainless steel to stop rusting.

3. Sieve pad/ Pre-filter:

· A sieve pad is existing on the top of the

cabinet through which the air passes into the cabinet.

· The sieve pad traps dirt particles and some

microorganisms from entering the working environment within the cabinet.

4. Fan/ Blower:

· A fan is existing below the sieve pad that

sucks in the air and moves it around in the cabinet.

· The fan also permits the movement of air

towards the HEPA sieve so that the remaining microbes become entombed while

passing through the sieve.

5. UV lamp:

· Some laminar flow hoods may have a UV

germicidal lamp that disinfects the interior of the cabinet and contents before

the operation.

· The UV lamp is to be turned on 15 minutes

before the process to stop the exposure of UV to the body surface of the user.

6. Fluorescent lamp:

· Florescent light is positioned inside the

cabinet to deliver proper light during the operation.

7. HEPA sieve:

· The High-efficiency particulate air sieve is

present within the cabinet which makes the setting more germ-free for the

operation.

· The Pre-filtered air passes through the sieve

which traps molds, bacteria, and other powder particles.

· The sieve safeguards a germ-free condition

inside the cabinet, thus plummeting the chances of contamination.

What are the kinds of laminar flow cabinets?

Contingent on the course of movement of air,

laminar flow cabinets are separated into two kinds:

Perpendicular laminar flow cabinet:

· In the perpendicular flow cabinets, the air transfers

from the top of the cabinet straight toward the bottom of the cabinet.

· A perpendicular airflow working bench does not

need as much depth and floor space as a flat airflow hood which makes it

wieldier and cuts the chances of airflow obstacles or movement of contaminated

air downstream.

· The perpendicular laminar flow cabinet is also

considered harmless as it doesn’t blow the air directly toward the person

carrying out the trials.

Flat laminar flow cabinet:

· In the flat laminar flow cabinets, the surrounding

air comes from behind the working bench, which is then distended by the blower

towards the HEPA sieves.

· The sieved air is then consumed in a flat

directly to the workplace environment.

· One benefit of this cabinet is that airflow

similar to the workplace cleanses the setting with a constant velocity.

· The eluent air directly hits the worker, which

might decrease the security level of this kind of laminar flow cabinets

available with laminar air flow dealers.

How does a laminar flow hood work?

· The principle of a

laminar flow cabinet is founded on the laminar stream of air through the

cabinet.

· The device works by

the use of an inward stream of air through one or more HEPA sieves to generate

a particulate-free environment.

· The air is taken

over a filtration system and then consumed across the work surface as a part of

the laminar flow of the air.

· The air first passes

through the sieve pad or pre-filter which permits a streamlined flow of air

into the cabinet.

· Next, the blower or

fan guides the air toward the HEPA sieves.

· The HEPA sieves then

trap the microorganisms, mushrooms, and other particulate materials so that the

air moving out of it is particulate-free air.

· Some of the waste

air then passes through the puncture present at the bottom rear end of the

cabinet, but most of it passes over the working bench while coming out of the

cabinet towards the face of the operator.

· The laminar flow

hood is surrounded on the sides, and continuous positive air pressure is upheld

to stop the intrusion of contaminated external air into the cabinet.

What is the process of operating a laminar

flow cabinet?

The process to be tracked while operating a

laminar flow cabinet is given below:

- Before running the laminar flow cabinet, the

cabinet must be checked to safeguard that nothing vulnerable to UV rays is

present inside the cabinet. - The glass buffer of the hood is then shut,

and the UV light is switched on. The UV light must be kept on for about 15

minutes to safeguard the surface sterilization of the working bench. - The UV light is then swapped off, and a

period of around 10 minutes is safe before the airflow is swapped on. - About 5 minutes before the operation begins,

the airflow is swapped on. - The glass shield is then unbolted, and the

fluorescent light is also swapped on during the operation. - To safeguard more protection, the working

bench of the cabinet can be disinfected with other antiseptics like 70%

alcohol. - Once the work is finished, the airflow and

florescent lamp both are shut and the glass buffer is also shut.