An anesthesia machine supplied by Anesthesia Machine Suppliers is used to produce and blend medical gases like oxygen or air and anesthetic agents to encourage and uphold anesthesia in patients. The process of anesthesia onsets with the oxygen stream from the pipeline or cylinder through the flowmeter. O2 streams through the vaporizer and picks up the anesthetic gases. The O2-anesthetic mixture then streams through the breathing circuit and into the patient’s lungs, typically by unprompted ventilation or normal respiration.

The Boyle′s machine has been the most often used anesthesia machine since it was industrialized in the early 20th century. This is a continuous-flow anesthesia machine, which is intended to provide a precise supply of medical gases merged with a precise concentration of anesthetic vapor and deliver this continuously to the patient at a precise pressure and stream. When essential, mechanical ventilation could be used contingent on the patient’s condition.

Though, with basic anesthesia machines, the following kinds of issues were faced:

- A higher degree of depletion of air and anesthetic agents.

- Machines were entirely mechanical systems with semi-open circuits and a high fresh gas stream.

- There were manifold connections, prone to stoppage, misconnection, kinking, leakage, or obstruction.

- The precision of flow meters was poor.

- There were no presentation response mechanisms such as alarms.

- Mechanical ventilation hampered the anesthetist, particularly in the case of more critical patients.

- The precision of anesthesia distribution and efficacy of the system was low and as a result, patient safety was often compromised.

Early on it was spotted (at the cost of many unlucky patients’ lives), that precisely controlling the amount of anesthetic agent and oxygen distributed and upholding ventilation of the lungs with oxygen-supplemented gas was critical to the security of the patient and also that this was not always realized professionally and accurately through a continuous stream or completely mechanical anesthesia units. So, there have been consistent efforts by Anesthesia Machine Manufacturers to improve the design of these machines to achieve the above objectives.

.

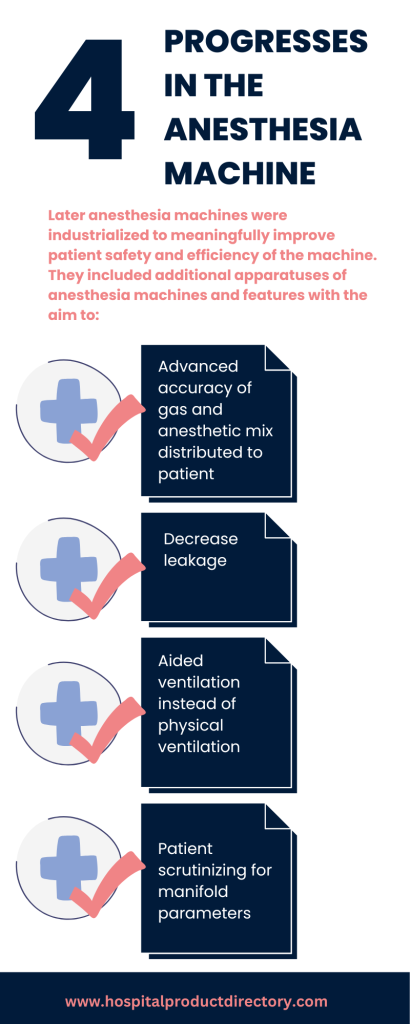

Progresses in the anesthesia machine

Later anesthesia machines were industrialized to meaningfully improve patient safety and efficiency of the machine. They included additional apparatuses of anesthesia machines and features with the aim to:

Advanced accuracy of gas and anesthetic mix distributed to patient – e.g. Flowmeters with Hypoxic guard and fail-safe. If the oxygen is exhausted/low, the fail-safe mechanism also decreases the nitrous oxide stream to stop a hypoxic gas combination from being distributed to the patient. It will also guarantee that when the flow of nitrous oxide is augmented, the stream of oxygen will be increased concurrently.

Decrease leakage – Pressure gauges, regulators, and ‘pop-off’ valves, to display gas pressure through the system and defend the machine components and patient from extreme rises.

Aided ventilation instead of physical ventilation – facilitation out the anesthetists and giving them the ability to handle more critically ill patients. Bellows ventilator type: Mostly, all anesthesia terminals comprise either hanging bellows or standing bellows. A standing bellow flops directly if there is a leak in the machine or if the patient becomes detached. A hanging bellow endures refilling even if there is a considerable leak. Most modern machines have a standing bellows ventilator as it gives a pictorial alarm about detaching leakage or lower gas levels.

Patient scrutinizing for manifold parameters – Systems for scrutinizing the patient’s heart rate, ECG, blood pressure and oxygen capacity, end-tidal carbon dioxide, and temperature are included. Patient scrutinizing is critical among the numerous components of the anesthesia machine.

The arrival of the Unified Anesthesia Terminal

Over time, the conformist anesthesia machine has progressed into an Innovative Carestation or anesthesia terminal. The terminals offer combined advanced patient scrutinizing, and use advanced electronics, software, and technology safeguarding advanced abilities for ventilation, monitoring, inhaled agent delivery, low-flow anesthesia, and closed-loop anesthesia. They could be flawlessly combined with Electronic Medical Records and Hospital Information Systems.

Due to the high degree of incorporation between the gas distribution system, ventilator, and monitors – it is possible to deliver tidal capacities precisely and remove numerous dangers related to the low-pressure system and oxygen flush. Suitable use can result in improved safety and the economy of anesthetic distribution and monitoring.

The Modern Anesthesia Terminal

A modern anesthesia terminal is an integrated unit comprising the following components:.

- Basic apparatuses of anesthesia machine unit (counting gas distribution, electronic flowmeters, vaporizers, breathing circuit, scavenging system)

- Cutting-edge Ventilation

- Anesthesia and patient observing system

- Integration with Electronic medical records

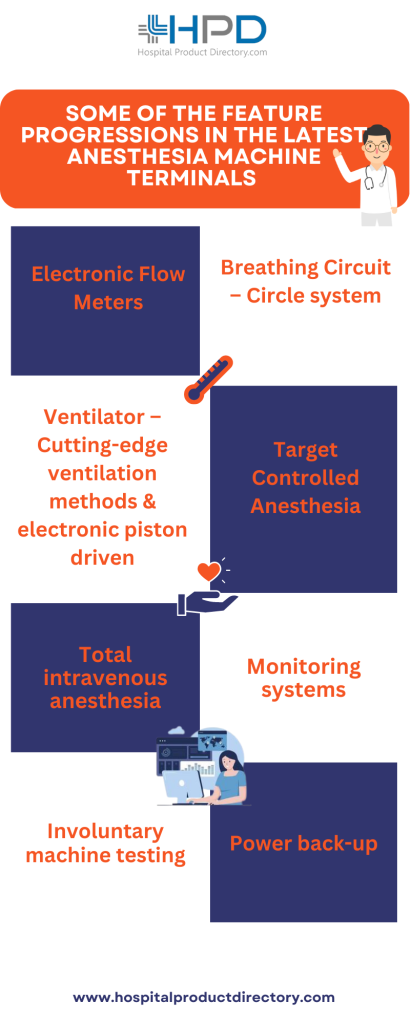

Some of the feature progressions in the latest terminals as compared to earlier generation anesthesia machines are as follows:

Electronic Flow Meters

State-of-the-art pressure transducers and electronically controlled flow control valves safeguard better precision of gas delivery. Electronic flowmeters are not only more precise but also do not have glitches connected to multiple mechanical parts which are prone to leaks and breakages. The information linked to the stream may be displayed either in digital or virtual form. Some apparatuses have conventional control handles and flow control valves but the flow information is shown electronically using electronic flow sensors and digital displays rather than glass flow tubes. These allow calmer conception and control of flow and also allow the export of electronic data to an information system.

Breathing Circuit – Circle system

Modern anesthesia machines feature loop absorber systems rather than open or semi-open circuits, fundamentally intended for low-flow anesthesia. Misconnections or stoppages are abridged and compressed circuits that allow rapid changes in gas composition at low flows. Water vapor or dampness preservation is better. Steeply mounted unidirectional valves presented in some newer models cut resistance to flow. Throwaway units of Carbon dioxide (CO2) absorbers and bypass valves are obtainable to safeguard standby without interruption of anesthesia gas distribution, leakage, or change in the gas mix.

Ventilator – Cutting-edge ventilation methods & electronic piston driven

Ventilators are one of the most significant apparatuses of the anesthesia machine. Newer systems come with ventilators that use electrically driven pistons or turbines to produce steam instead of pressurized oxygen in traditional ventilators. This saves oxygen significantly and can be consumed only for the patient’s breathing circuits.

Target Controlled Anesthesia

The fully combined and involuntary system has provided Target Controlled Anesthesia (TCA) capabilities. With TCA ability the anesthetist can set the target end-tidal oxygen and anesthetic agent standards and the combined system constantly monitors these values and mechanically regulates the gas distribution and total flow to uphold the set target values. Smart inherent precautions help defend against over-delivery and under-delivery of agents and hypoxia. This provides cost-effective anesthesia by keeping gas and agent utilization to an out-and-out minimum.

Total intravenous anesthesia

The alternative technique to inhalational anesthesia is providing total Intravenous Anesthesia. This could also be highly mechanized with a software system assimilating data from the anesthesia system, and drug database, and feeding into syringe pumps to automatically set quantities for drugs being directed.

Monitoring systems

United anesthesia and patient monitoring systems have been one of the most significant progressions in anesthesia terminals. The monitoring systems have been marked with sophisticated visual and audio electronic alarms, branded based on the urgency of circumstances and several new monitoring capabilities e.g., complex respiratory waveforms.

Most modern anesthesia monitoring systems have a supple display screen that can be constructed according to partialities from widespread medical parameters that comprise hemodynamic, respiration, and ventilation monitoring, temperature, anesthesia depth monitoring, and anesthesia gas monitoring.

Involuntary machine testing

In older anesthesia machines escapes, misconnections, or detaches would have to be manually checked. This may not be done often or properly. Most modern anesthesia distribution systems complete some degree of self-test and have the aptitude to notice and report any faults if not all, such as valve failure.

Automatic record-keeping

Anesthesia Information Management System comprises a mixture of hardware and software that interface with intraoperative monitors and mechanically record data from the monitors like vital signs and ventilator strictures for charting purposes. This could be combined and be a portion of the hospital information system and Electronic medical records.

Power back-up

Since all modern terminals have more complex electronically measured systems they depend severely on an incessant supply of electricity and have battery backup. It is significant to know the amount and period of battery backup available so that in case of power failure appropriate manual backup mechanisms are kept prepared.

Some of the security and functioning features existing in newer machines obtainable with Anesthesia Machine Dealers may be non-existent in machines available earlier. Though, they were intended to be operated without much electricity, using compressed gas power for the ventilator and suction apparatus. Current machines which are highly electronic, need battery standby in every constituent, which can be only for a restricted period, say 30 minutes. When faced with financial constraints and possibly limited utilization, one may not be in a position to go for an innovative full-fledged anesthesia terminal. In this case, a detailed approach to feature contrast would be essential to make the right purchase.