We’ve covered the rank of germ-free environments in hospitals many times. All goals are to defend patients from further contagions like hospital-acquired contagions. The ICU and the operating room particularly need to be inspected for pathogens due to the subtle state of their patients.

One way to safeguard patient security is to make sure hospital provisions and equipment like surgical tools are as sterile as possible. This is the role of the central sterile services department (CSSD), also named the sterilized dispensation department, disinfected processing, central source department, or central supply.

The CSSD offers disinfected materials to wards, operating rooms, transplant units, and outpatient sections. Contingent on the hospital, its errands may include:

- Cleansing of instruments using equipment made by CSSD Equipment Manufacturers for surgery, the delivery room, emergency section, nursing sections, clinics, and/or offsite urgent care facilities.

- Instrument set assemblage and packing.

- Purification services.

- Patient gear scrubbing, delivery, and billing.

- Case wagon structure for operation and/or the delivery room.

Earliest Roots

The washing of medical instruments to stop infection has a long and all-embracing history. In 3000 BC the Egyptians used terrain and tar as disinfectants. The vapors from burning sulfur were found to have been used to rinse objects of communicable material. The Greek medical practitioner Galen (130-200 AD) cared for injured Roman gladiators by broiling his instruments before use.

Refillable Medical Equipment: A Dissection

Much of the work done by the CSSD revolves around recyclable medical equipment or RME. These can comprise any medical substances ranging from stainless steel surgical tools to IV pumps and crash carts. They are detached into three modules:

- Non-critical

- Semi-critical

- Critical

Non-critical substances comprise such equipment as IV poles and pumps. The purification in this class can be achieved with most hospital antiseptics.

Semi-critical items comprise equipment that will have contact with complete mucous sheaths like the inside of the nose, mouth, or anus. The endoscope like those used in colonoscopies is an instance of such a tool. Naturally, substances in this class require high-level antiseptics such as glutaraldehyde solution, peracetic acid, or hydrogen peroxide plasma to disinfect them.

Critical items include any instrument which will be presented into a patient’s bloodstream or in a normally germ-free part of the body. The use of disinfectants for such gear is a must.

Major Parts of Sterile Dispensation

Sterile dispensation sections are typically divided into four major parts:

- Cleansing

- Assembly and sterilized dispensation (sterilization)

- Sterile storing

- Delivery

Errands in each part are chiefly handled by the sterile dispensation technicians.

Cleansing Area

Cleansing is the physical and chemical method that renders medical equipment dirtied with harmful microbial life forms safe for further treatment. In the cleansing area, RME is gutted and cleansed by various physical, mechanical, and chemical washing means using equipment supplied by CSSD Equipment Supplier.

Cleansing procedures include:

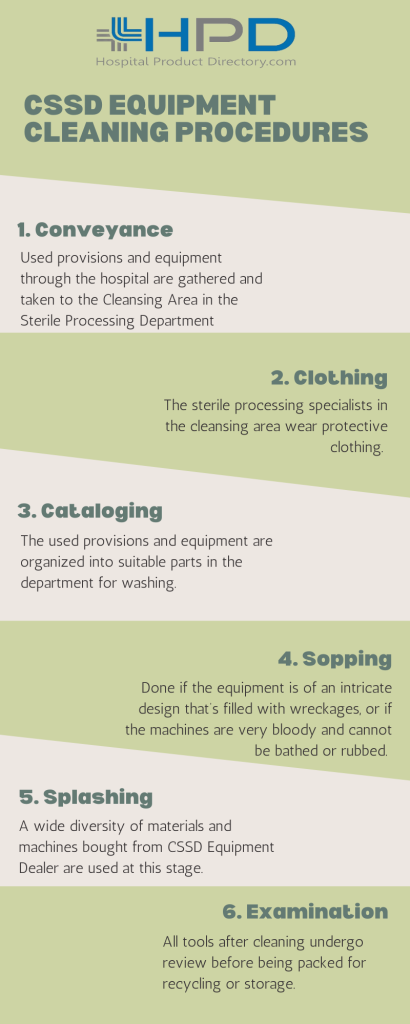

- Conveyance – Used provisions and equipment through the hospital are gathered and taken to the Cleansing Area in the Sterile Processing Department. The effort is made to evade pollution of personnel or any part of the hospital.

- Clothing – The sterile processing specialists in the cleansing area wear protective clothing. This arrays from a clean uniform enclosed by a moisture-resistant fence, shoe refuges, and rubber or plastic gloves, to security goggles and face masks.

- Cataloging – The used provisions and equipment are organized into suitable parts in the department for washing.

- Sopping – Done if the equipment is of an intricate design that’s filled with wreckages, or if the machines are very bloody and cannot be bathed or rubbed.

- Splashing – A wide diversity of materials and machines bought from CSSD Equipment Dealerare used at this stage. The cleaner must be compatible with the materials in the machine and suited for the kind of spoilage. A washer/decontaminator is used to tidy heat-tolerant substances. An ultrasonic washer is used to eliminate fine dirt from medical instruments after manual washing and purification.

Tunnel washers and cart washers bear a resemblance to mini car-washes with most permitting completely hands-off processing.

- Examination – All tools after cleaning undergo review before being packed for recycling or storage.

Assembly and Sterile Dispensation Area

Items coming from the cleansing area are collected and equipped here for the issue, or to be directed back into the hospital for use. Others are put into the Germ-free Storing Area. Substances are also brought into the part to undergo further purification.

Purification is the procedure of abolishing all living organisms on an object. It’s also called a germ-free dispensation. It varies from cleansing in the processes and equipment used. The sterile dispensation technicians are also accountable for carrying out the purification duties.

The CSSD has manifold approaches to disinfecting medical items. Which one is used is contingent on issues like costs, possible hazards to workers, the competence of method, time, and configuration of the materials being pasteurized.

Sterile Storing Area

Items transported to the sterile storing area are held there until it’s time for them to be delivered. The part is prudently controlled from air temperature to dampness to stop the growth of microorganisms.

Substances are also packed to maintain their sterility. Evidence like dates is marked for example. This supports regulating the item’s shelf-life.

Delivery Area

When pasteurized items are ready to be issued, it’s transported to the Delivery Area.

Several purposes are carried out at this site. Case cart groundwork and distribution; exchange cart list, and telephone order and requisition-order filling are just a few instances of these activities.

Medical Computers and the CSSD

The position of upholding a sterile setting in CSSD poses unique supplies for medical computer use in the department.

Antibacterial – You don’t want microorganisms growing on the exteriors of the computer. While sterile sprays are obtainable, such possessions can be parched into the casing’s resin. They don’t need to be reapplied and constrain development even if the casing is injured or damaged.

Fanless – Computers chilled with fans take in pathogens in the air and gust them around the room. That’s the last article you want in any part of the CSSD. Medical computers with a fanless plan do not generate such glitches, keeping cool using heatsinks.

IP65 – An wayward spray from water, cleaners, or body liquids can cause hurt if it gets inside a computer. Medical grade screens and medical tablets with an IP65 rating are closed against such unintentional splashes.

Conclusion

Disinfected processing sections like the CSSD are accountable for the cleansing, sterilization, storing, and delivery of reusable medical equipment throughout a hospital. Contagions can be unsafe to patients, many of whom are in critical condition.